Review Article - (2025) Volume 19, Issue 1

Research Opportunity in Developing Floating Flexible Tanks for Fish Farming Disorder

J.J. Wiegerink* and

C.M. Wang

Department of Paediatric Neurology, University of Queensland, Brisbane, Australia

*Correspondence:

J.J. Wiegerink, Department of Paediatric Neurology, University of Queensland, Brisbane,

Australia,

Email:

Received: 28-May-2024, Manuscript No. IPFS-24-14909;

Editor assigned: 30-May-2024, Pre QC No. IPFS-24-14909(PQ);

Reviewed: 13-Jun-2024, QC No. IPFS-24-14909;

Revised: 03-Mar-2025, Manuscript No. IPFS-24-14909(R);

Published:

10-Mar-2025

Abstract

Fish farming in novel floating flexible containments is a promising proposition to minimise the CAPEX of the current floating closed containment tank technology. Floating tanks have tangible benefits over the use of open net cages and a lower CAPEX should incentivise fish farmers to adopt this technology faster. This short-communication suggests future research activities focusing on understanding and predicting the structural responses and the associated stresses in the flexible bag material with the view to optimise and improve flexible containment tank designs.

Keywords

Closed containment tanks; Fish farming; Flexible bags; Research opportunities

Introduction

Fish farming in floating closed tanks

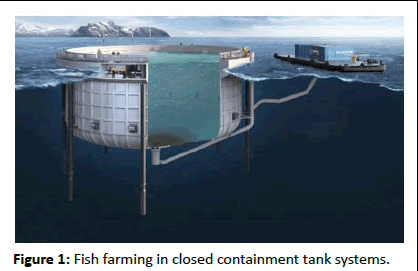

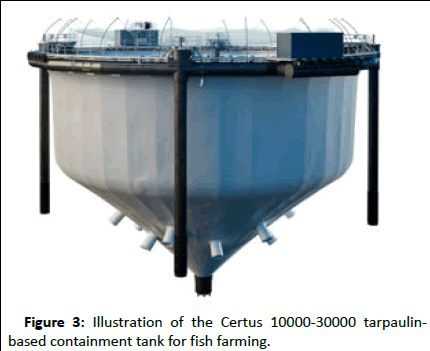

The fish farming industry requires new innovative solutions to facilitate its rapid growth and keep up with the global increasing demand for fish. With approximately 70% of the earth's surface covered with water, fish farming in floating marine structures has the potential to realise this growth as opposed to farming on land. Currently, marine fish farmers primarily use floating opennet cages, which are proven to be effective. However, increasing criticism and concerns about the ecological interactions of farming in these cages sets the need for sustainable solutions. Especially when upscaling fish farming activities nearshore. One of the solutions is to use floating closed containment tanks for fish farming [1-3]. Figure 1 illustrates what fish farming in these tanks look like. The tank wall creates a physical barrier between the contained cultured water and surrounding waterbodies. Before water is pumped into the tank, it gets cleaned, treated and oxygenated to create optimal conditions for the fish. The physical barrier excludes interaction with the external environment. Waste products like fish faeces, excess feed and dead fish are readily collected from the bottom of the containment tank and processed externally [4]. Unlike open-net cages, fish farming in closed tanks has the following benefits: It excludes the negative impacts of jellyfish swarms, algae bloom and sea lice and prevents severe water quality fluctuations. The physical barrier prevents the interaction with predators like seals and sharks. Also, cooler water can be pumped from greater depths into the containment tank to avoid amoebic gill disease and sea lice as a result of increasing surface water temperatures. When water is pumped back into the surrounding ecosystems, it can be filtered, treated and oxygenated for a sustainable operation without ecological impact.

Figure 1: Fish farming in closed containment tank systems.

Literature Review

Fish farming systems in waves

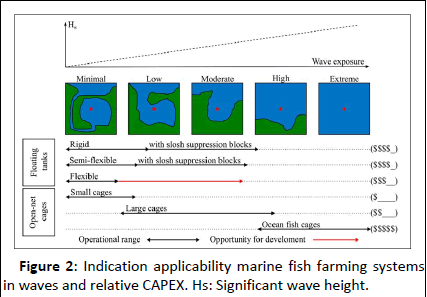

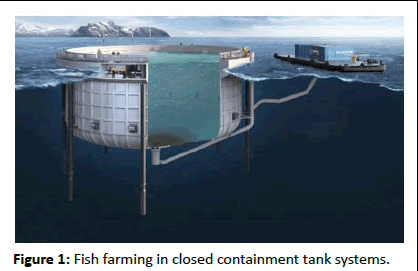

Fish farming systems can be divided into two main categories: Open-net cages and closed containment tanks. For each category, Figure 2 indicates the applicability of these marine fish farming systems for various wave exposures. Open-net systems are applied in both low and extreme wave conditions. Their design varies from small collar structures with a net suspended below to offshore semi-submersible platforms covered with netting to contain the fish [5,6]. Floating closed containment tanks are divided into three categories based on their structural stiffness: Flexible, semi-rigid and rigid [7]. Rigid tanks are typically made from steel or structural concrete, have large inertia against motion and show insignificant deformations under wave loading [8]. Semi-flexible tanks, typically made from HDPE or fibreglass-reinforced polymer, can show hydroelastic responses and tank deformation when excited by waves [9]. This is an essential design consideration and has led to the failure of the containment when hydroelastic coupling occurs with specific sloshing modes [10]. Developed a solution to extend the operational range of rigid containment tanks with slosh suppression block. They hypothesised that semi-flexible containment tanks could be stiffened with slosh suppression blocks, potentially preventing structural deformations under wave loading. Flexible tanks, also referred a bags, are primarily applied in sheltered farming sites with minimal wave action to prevent snapping loads in the tarpaulin tank membrane [11]. Flexible tanks typically have a rigid collar from which the tarpaulin is suspended. It has a positive waterhead relative to the surrounding water to keep the bag in shape. While still being more expensive than small or large net cages, floating flexible tanks have a significantly lower material requirement than semirigid or rigid tanks and therefore, lower Capital Expenditure (CAPEX). The lower CAPEX forms an opportunity to get fish farmers to adopt closed containment tank technology faster and take advantage of the associated benefits. However, floating flexible tanks are not yet proven under wave action, which poses an exciting development opportunity.

Figure 2: Indication applicability marine fish farming systems in waves and relative CAPEX. Hs: Significant wave height.

Discussion

Floating tanks with a lower CAPEX

The adoption of closed containment tank technology among fish farmers is slow and reducing the CAPEX is a pivotal element in making this technology more attractive. Estimates show that the return on invested capital of closed containment tank systems can be similar to that of currently used open-net cages. Particularly, when utilising the economy of scale, floating containment tank technology can become a profitable alternative. Primary factors contributing to the profitability are healthier fish with lower mortality rates and the fish grow faster in their optimised environment. Healthier fish results in less requirement for fish treatments and therefore a lower OPEX. These benefits outweigh the higher OPEX to pump and condition the water. The higher production output offsets the initial cost over the design life of the floating closed tanks. There are currently approximately ten commercially operating floating closed containment tank systems worldwide and ongoing developments demonstrate the commercial viability of this novel industry. While semi-flexible or rigid tanks are more robust and less prone to damage if well looked after and correctly engineered, flexible bags have considerable commercial potential. For extra security, the tarpaulin bags can be combined with an internal or external net to prevent possible fish escapes in case of a damaged bag. Another benefit of flexible bags is that they can be folded and transported easily, making their fabrication location independent of the fish farming site or local fabrication sites.

Current state lexible bag technology

Research on flexible bag structures under wave and current loading has been ongoing. Discusses important design parameters of the flexible bag, including having a positive differential pressure inside the bag is essential to keeping the bag in shape. Also, having a positive buoyancy collar with sufficient waterplane stiffness is required. Showed that the hydromechanic behaviour of the containment depends strongly on the stiffness of the collar. With the increasing interest into fish farming in floating closed containments, strand dedicated her research towards better understanding the sea loads on closed flexible cages of different filling levels. One of the findings reported a significant increase of the drag forces when the flexible bag was under filled. Also indicated the importance of scaling the stiffness of the bag material in model scale experiments and presented a method to model a 2D flexible bag in waves as a starting point for 3D analysis. Following the research on modelling rigid tanks and additional experiments with a flexible bag in waves, they plan to continue modelling 3D flexible bags in waves with the particle method.

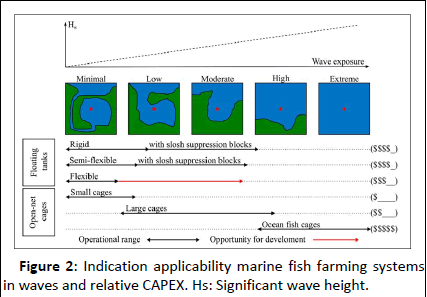

The French company Serge Ferrari group is leading in developing the tarpaulin products used for flexible floating tanks. They first tested the flexible tank technology in 2014, where salmon in the post-smolts stage were grown from 60 g-350 g in a 2500 m3 floating flexible tank. The latest sea trials, in 2022, include the Certus 15000 flexible tank that holds postsmolts 650 g-2 kg (Figure 3). Learnings from continuous sea trials led to the innovative flexible composite tarpaulin named Biobrane Aqua. A spin-off company, S3A-systems, was founded to deliver floating flexible containment tanks for the aquaculture industry. S3A-systems has the expertise and specialised tarpaulin bonding procedures to fabricate flexible tanks and ensure the structural integrity of the bag. Their technology has primarily been tested at protected and sheltered farming sites characterised as low-energy environments with minimal wave and current action.

Figure 3: Illustration of the Certus 10000-30000 tarpaulinbased containment tank for fish farming.

Conclusion

The flexible bag technology is an exciting proposition due to the lower CAPEX when compared to other floating closed containment tank designs. The utilisation of containment tanks for fish farming encourages the sustainable growth of the fish farming industry and addresses community concerns about the ecological interaction of fish farming in open-net cages. The outlined research opportunity herein should aim to explore the performance of floating flexible tarpaulin tanks in a more exposed wave climate so that fish farmers can benefit from more affordable closed containment tank technology. Suggested research activities are:

- Undertaking an experimental campaign with a scale model of a flexible containment tank in waves. This campaign should include stress measurements in the membrane at the connection points to the collar. Coping strategies in rough weather events should be developed and tested to prevent snap loads in the tarpaulin.

- Develop a calculation tool to predict flexible bags' behaviour in waves and determine the stresses in the flexible bag material.

- With the obtained insights, novel flexible bag designs should be created and prototypes tested in a relevant environment.

- Technological advancements with flexible tank technology and a better understanding of their behaviour in waves could lead to the development of more cost-effective containment tanks and a faster adoption of closed containment tank technology among fish farmers.

References

- Chu YI, Wang CM, Park JC, Lader PF (2020) Review of cage and containment tank designs for offshore fish farming. Aquaculture 519: 734928.

[Crossref] [Google Scholar]

- Dong S, Zhao H, Zhou J, Li Q, Kitazawa D (2022) An experimental analysis on motion characteristics of a closed fish cage including internal sloshing flows. Conf Proc Jpn Soc Nav Archit Ocean Eng 35: 517–521.

[Crossref] [Google Scholar]

- Chang YC, Zhang X, Khan MI (2022) The impact of the COVID-19 on China's fisheries sector and its countermeasures. Ocean Coast Manag 216: 105975.

[Crossref] [Google Scholar]

- Lader P, Fredriksson DW, Volent Z, DeCew J, Rosten T, et al. (2017) Wave response of closed flexible bags. J Offshore Mech Arct Eng 139: 051301.

[Crossref] [Google Scholar]

- Lader P, Fredriksson DW, Volent Z, DeCew J, Rosten T, et al. (2015) Drag forces on and deformation of, closed flexible bags. J Offshore Mech Arct Eng 137: 041202.

[Crossref] [Google Scholar]

- Mukhlas M, Lader PF, Kristiansen D, Kristiansen T, Kanazawa M (2021) Bag and floater motions of a fabric membrane cage. J Fluids Struct 106: 103353.

[Crossref] [Google Scholar]

- Shen Y, Firoozkoohi R, Greco M, Faltinsen OM (2021) Experimental investigation of a closed vertical cylinder-shaped fish cage in waves. Ocean Eng 236: 109444.

[Crossref] [Google Scholar]

- Strand IM, Faltinsen OM (2019) Linear wave response of a 2D closed flexible fish cage. J Fluids Struct 87: 58-83.

[Crossref] [Google Scholar]

- Strand IM, Sørensen AJ, Volent Z, Lader P (2016) Experimental study of current forces and deformations on a half ellipsoidal closed flexible fish cage. J Fluids Struct 65: 108-120.

[Crossref] [Google Scholar]

- Wang CM, Wiegerink J, Leow BT (2020) Opportunities for floating closed containment systems for fish farming. J Aquac Mar Biol 9: 123-127.

[Crossref] [Google Scholar]

- Wiegerink JJ, Baldock TE, Callaghan DP, Wang CM (2023) Experimental study on hydrodynamic response of a floating rigid fish tank model with slosh suppression blocks. Ocean Eng 273: 113772.

[Crossref] [Google Scholar]

Citation: Wiegerink JJ, Wang CM (2025) Research Opportunity in Developing Floating Flexible Tanks for Fish Farming Disorder. J Fish Sci, Vol:19 No:1